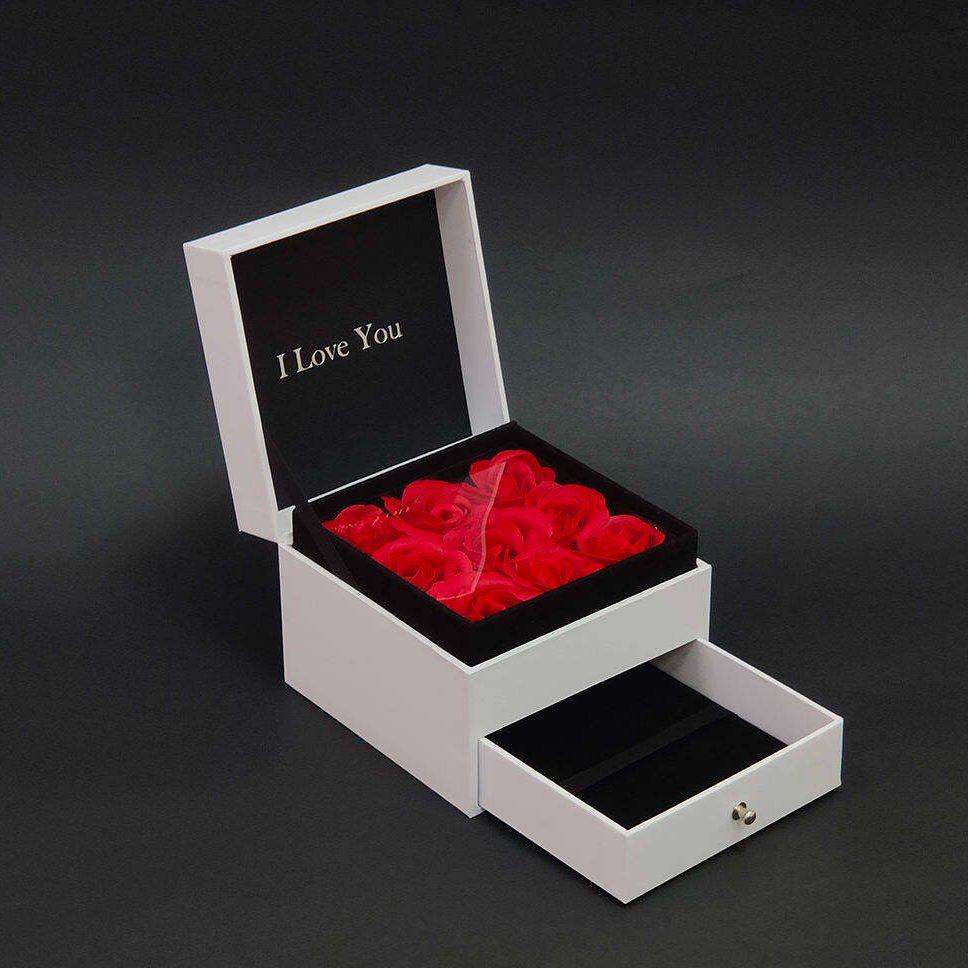

CHANG FA “Ihastuttavat Aarteet”korularakkaon täydellinen koti arvokkaille asioillesi. Se on tyylikäs ja hienostunut taideteos, joka on suunniteltu parantamaan tapaa, jolla esittelet arvokkaimmat esineesi.

Valmistettu parhaista materiaaleista, tämä korurasia tarjoaa tyyliä sekä käytännöllisyyttä. Saatavilla on monia erilaisia värejä ja viimeistelyjä sen ylelliselle ulkopinnalle, joka lisää glamouria mihin tahansa meikkipöytään tai pukeutumispöytään.

Useissa osastoissa ja järjestäjissä sisällä se tarjoaa tarpeeksi tilaa kaikille sormuksillesi, korvakoruille, kaulaketjuille tai rannekoruille. Ei enää sotkeutuneita ketjuja tai kadonneita korvakoruja – kaikki voi löytää paikkansa CHANG FA "Glamorous Treasures" korurasiasta.

Tee tästä laatikosta erityinen laittamalla sinne oma logosi tai muita henkilökohtaisia yksityiskohtia. Tämä kaunis korurasia voi muuttua ainutlaatuiseksi lahjaksi jollekin rakkaalle tai vain toiseksi upeaksi asiaksi, joka sinulla on.

Chang Fa tietää, että korut eivät ole vain pukeutumista varten, vaan myös itseilmaisun väline. Tämän osoittamiseksi brändi tarjoaa mahdollisuuden räätälöidä korulaatikoitaan, jotta asiakkaat voivat personoida omat säilytysratkaisunsa. Tämä personointi voi ilmetä eri muodoissa, kuten nimen tai erityisen viestin kaiverruksessa, tai jopa valitsemalla mukautettu viimeistely tai väri, joka vastaa omistajan luonteenpiirteitä. Nämä henkilökohtaiset yksityiskohdat muuntavat jokaisen laatikon todelliseksi muiston esineeksi, joten se ei ole vain säilytystä, vaan myös yksilöllinen edustus. Räätälöintiprosessi on hyvin hallittu laadun ja laatikon eleganssin ylläpitämiseksi samalla, kun luodaan ainutlaatuisuutta sen sisällä. Chang Fa mahdollistaa asiakkailleen arvokkaiden korulaatikoiden kehittämisen tarjoamalla sellaisia räätälöityjä vaihtoehtoja kuin edellä mainitut, jotka ovat yhtä poikkeuksellisia kuin niiden sisältämät jalokivet. Tämän seurauksena mikä tahansa Chang Fa -korulaatikko on erinomainen lahja rakkaalle tai merkityksellinen lisä omaan kokoelmaan.

Jokainen Chang Fakorularakkaon rakennettu vertaansa vailla olevalla käsityötaidolla sen ytimessä. Tämä sitoutuminen näkyy jokaisessa yksityiskohdassa – materiaalivalinnasta monimutkaiseen suunnittelun toteutuksen tarkkuuteen. Chang Fan käsityöläiset käyttävät sekä perinteisiä taitoja että moderneja menetelmiä luomisprosessinsa aikana, jotta ne muuttuvat hyödyllisiksi työkaluksi samalla kun ne näyttävät hyvältä. Se alkaa parhaiden laatumateriaalien, kuten eksoottisten puiden tai metallien, hankkimisesta, jotka eivät vain kestä pitkään, vaan myös lisäävät viehätystä missä tahansa niitä käytetään. Sitten jokainen kappale käy läpi huolellisen rakentamisen, jossa kiinnitetään huomiota jopa saumoihin, liitoksiin, viimeistelyihin jne., luoden näin esineen, joka toimii yhtä lailla suojana koruillesi kuin erottuu taiteellisesti. Tämän brändin osoittama käsityötaidot edustavat suurta lahjakkuutta ja omaperäisyyttä, mikä tekee näistä tuotteista ainutlaatuisia kappaleita, jotka ilmentävät erinomaisuutta, joka liittyy tällaiseen nimeen. Niiden tulisi kestää ajan testi, tarjoten ikuisesti tyylikkyyttä yhdessä käytettävyyden kanssa, jota on arvostettu vuosisatojen ajan.

- Se on vain yksi asia.lisävarusteet, akorularakkaon ikuisesti rakastetun esineen kumppani. Tunnistaen, että nämä esineet palvelevat sekä toiminnallisuutta että esteettisyyttä, Chang Fa valmistaa laatikoita, jotka mullistavat arvokkaiden esineiden säilyttämisen ja esittelyn. Ne ovat enemmän kuin vain säilytysastioita; ne ovat kauneuden ja hyödyllisyyden yhdistelmä, joka on suunniteltu sulautumaan saumattomasti mihin tahansa sisustukseen tuoden samalla ripauksen tyyliä jokaiseen tilaan. Jokaisessa ChangFan korurasian suunnittelussa ei jätetä huomiotta yksityiskohtia; sen ulkopintojen on oltava tyylikkäitä ja sisätilojen visuaalisesti houkuttelevia mutta myös käytännöllisiä. He vuoraavat nämä sileän näköiset ulkopinnat pehmeillä ylellisillä kankailla, mikä tekee niistä turvallisia turvapaikkoja kaikille koruille. Tämän vuoksi tämä huolellinen taideteos varmistaa, että jokainen kaulaketju ei vain saa tilaa, vaan myös esitellään mahdollisimman houkuttelevalla tavalla ottaen huomioon sellaiset seikat kuin useat osastot, turvalliset sulkemiset ja joskus peili kätevyyden vuoksi. Kaikki korut säilytetään kauniisti, kun ne asetetaan yhteen näistä Chang Fan korurasioista, muuttaen tavallisen säilytyksen taiteelliseksi ilmaisuksi.

Luksus tuodaan arkeen Chang Fa -korurasioden kautta. Sen sijaan, että ne olisivat vain toiminnallisia säilytysastioita, nämä laatikot on suunniteltu saamaan meidät arvostamaan kauneutta päivittäisessä elämässämme. Tarjoamalla omistettuja alueita korujen säilyttämiseen, Chang Fa:n laatikot auttavat luomaan rituaaleja ja edistämään tietoisuutta pukeutumisessa työhön tai vapaa-aikaan. Joka kerta, kun avaat Chang Fa -korurasiasi, löydät siististi järjestellyn ja kauniisti esille asetetun kokoelman, joka kutsuu sinua ihailemaan jokaisen esineen käsityötä. Lisäksi laatikon toiminnallisuuden ja eleganssin kautta parannetaan kokonaiskokemustasi, mikä mahdollistaa päivittäisen vuorovaikutuksen korujesi kanssa sen käyttäjäystävällisen luonteen ansiosta. Lisäksi niiden korkealaatuiset komponentit ja ajaton muotoilu tarkoittavat, että nämä säilyttimet ovat aina tyylikkäitä ja käytännöllisiä osia elämäntavastasi tulevina vuosina. Chang Fa:lle luksus ei kuitenkaan tule esiin vain erityisinä tilaisuuksina; se pysyy kanssasi joka minuutti, jolloin kaikki näyttää ympärilläsi poikkeukselliselta.

Dongguan ChangFa Packaging Materials Workcenter on johtava valmistaja, joka on erikoistunut erilaisiin pakkaustuotteisiin, mukaan lukien pakkauslaatikot, lahjarasiat ja korulaatikot, ja jolla on yli 21 vuoden kokemus. Sijaitsemme Dongguan Cityssä, ja meillä on kehittyneitä laitteita ja ohjelmistoja, jotka takaavat korkealaatuiset tuotteet kilpailukykyiseen hintaan.

Kannettava ja monipuolinen, ihanteellinen pienten korujen säilyttämiseen ja järjestämiseen liikkeellä ollessasi

Kompakti ja joustava, täydellinen korujen järjestämiseen liikkeellä ollessa

Ympäristöystävällinen ja biohajoava, kestävä valinta tavaroiden kuljettamiseen ja samalla vähentää muovijätettä

Monipuolinen ja muokattavissa, parantaa lahjojen esittelyä ja tarjoaa samalla kätevän pakkausratkaisun

03

Jun

03

Jun

03

JunPaperikoristeemme on valmistettu yhdistämällä paperia ja päällystettyä paperia. Tämä tuottaa kestävän mutta elegantin pakkausratkaisun, joka tarjoaa sekä suojan että visuaalista viehätystä koruillesi.

Kyllä, tarjoamme räätälöityjä koko vaihtoehtoja, jotta voimme mukauttaa ne erityisiin koruosi, sekä erilaisia väri vaihtoehtoja, mukaan lukien Pantone värit, CMYK-tulostus ja räätälöity väri vastaavuus. Tämä antaa sinulle mahdollisuuden luoda pakkausta, joka täydentää täydellisesti brändiäsi tai tuotteen esteettisyyttä.

Tarjoamme valikoiman lisävarusteita parantaaksemme paperikoristeiden toimivuutta ja esittelyä, mukaan lukien nauhat, EVA-vaahtomuoviset sisäosat, PET VAC (muovista tyhjömuotoiltuja tarjottimia), paperitarjottimia tai sieni sisäosia. Nämä lisävarusteet auttavat suojaamaan ja esittelemään korusi tehokkaasti.

Kyllä, paperikartonkiset korurasiamme on valmistettu kierrätettävistä materiaaleista, mikä tekee niistä ympäristöystävällisen pakkausvaihtoehdon. Valitsemalla ympäristöystävälliset pakkausratkaisumme voit minimoida ympäristövaikutuksesi samalla kun toimitat korkealaatuisia tuotteita asiakkaille.

Paperikartonkiset korurasiat lähetetään standardipakkauksissa varmistaaksemme niiden turvallisuuden kuljetuksen aikana. Huolehdimme suuresti jokaisen rasian turvallisesta pakkaamisesta estääksemme vaurioita lähetyksen aikana, jotta korusi saapuvat moitteettomassa kunnossa.